Marietta Off: 770-262-7375

Fairburn Off: 770-262-7375

Gutters

Aluminum gutters are the most popular option on today's market due to their blend of affordability, style, and durability. Finley's Roofing installs custom made 6-inch seamless aluminum gutters with hidden fasteners, which gives you the look you want for your home and the performance you need. Finley's custom made gutters are not made from flimsy lumber yard grade metals, but from strong and sturdy .027 and .032 gauge aluminum. We use high quality Senox metal coils to make our gutters, which comes with a 50 Year Baked-on Aluminum Paint Warranty.

The Benefits of Seamless Aluminum Gutters

There are a number of reasons why many homeowners choose seamless aluminum gutters over other types of gutters. Consider the following advantages:

- Seamless lengths: Seamless gutters are custom cut to the length required, eliminating the need for seams, which weakens the gutter and can lead to leaks.

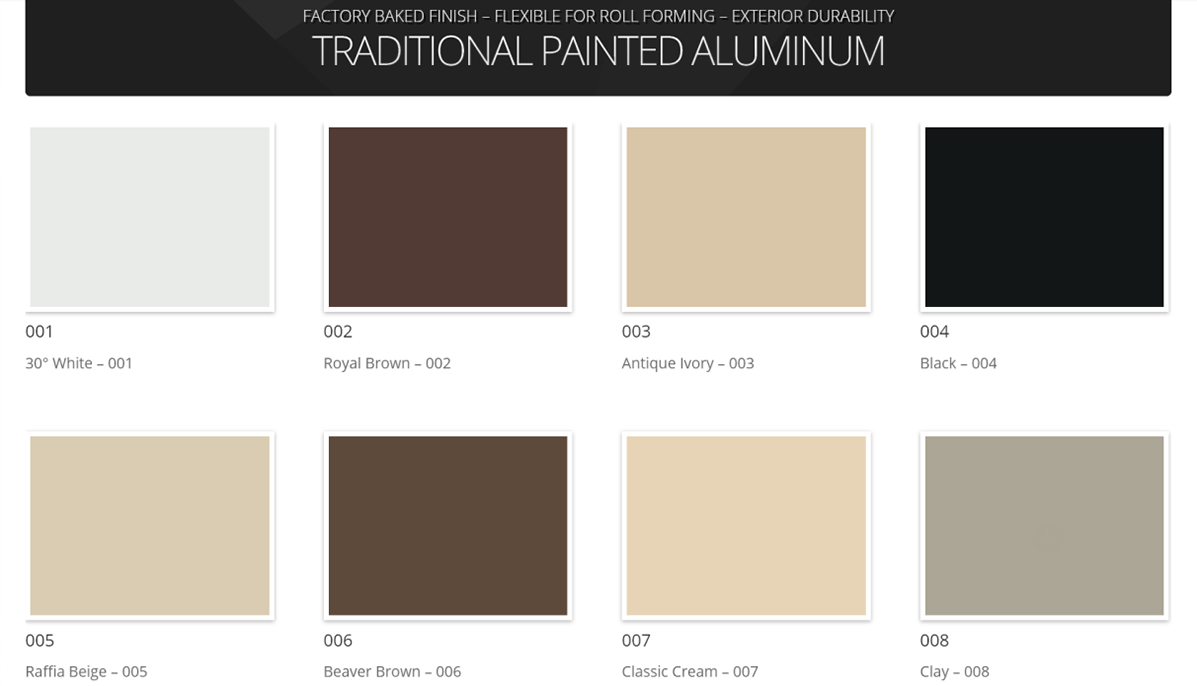

- Durable, factory-applied finish: Aluminum gutters come with a factory-applied finish that is available in a wide variety of colors to match your home and/or roof. The finish won't wear off unless you have to touch up scratched areas.

- Installed with hidden fastener brackets: Finley's custom gutters are not installed with unattractive gutter spikes, which can come loose over time and allow gutters to sag or fall off. Our gutters are secured to your fascia boards with special screw-in hidden gutter hangers that keeps your gutters safely in place indefinitely.

- No rust or corrosion: Aluminum won't rust or corrode, making it truly a no-maintenance material.

- Affordability: Seamless aluminum gutters cost less than other types of gutters while providing equal performance and a great finished appearance

How Our Custom Gutters Are Fabricated And Installed

|

1. From flat to formed: This K-profile gutter starts out as a flat sheet of aluminum. The gutter machine forms the profile, enabling the crew to create seamless gutters of any length. After the machine trims the gutter to the required length, workers attach end caps, then crimp and seal the caps to make the gutter watertight. |

|

2. Brackets add strength: These cross braces are installed every 36 inches or so to stiffen the gutter. The brackets also provide attachment points for screwing the gutter to the fascia board during gutter installation. |

|

3. Fastened to the fascia: Driving a screw through each gutter bracket and into the fascia board anchors the gutter in place. Each gutter section is pitched so that water can drain toward the drop outlet for the downspout. |

|

4. Down the drain: Downspouts are assembled from elbows and straight sections, then screwed to the gutter drop outlets and to the wall of the house. |

Custom Gutter Colors